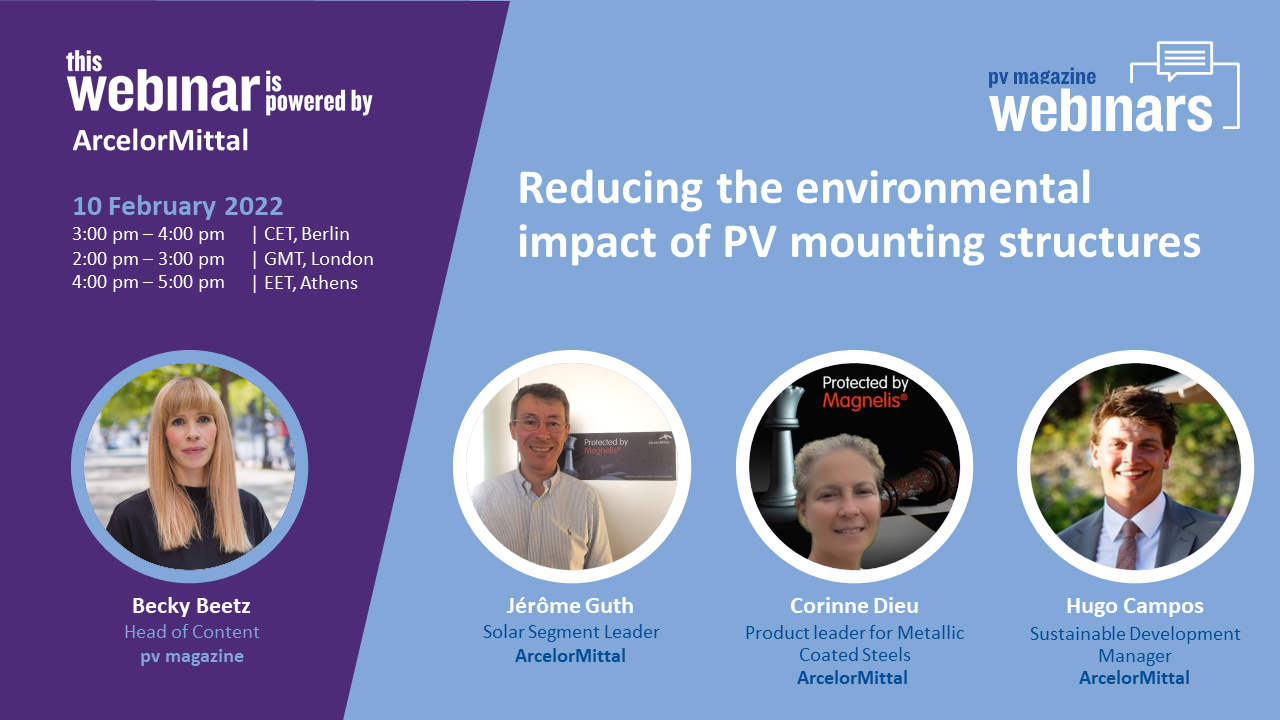

Thursday 10 February 2022, 15:00 – 16:00 CET.

In partnership with PV Magazine, ArcelorMittal will hold a webinar on sustainability and CO2 footprint reduction of solar mounting structures.

Click on the image to register to the webinar

Sustainability and the environmental impact of PV plants is fast climbing up the agenda. Indeed, it is becoming increasingly essential to consider the entire life cycle of PV when making decisions about materials and products. For PV plants, mounting systems have a key role to play in improving solar’s green credentials, from the perspective of both projects and companies.

Steel is the material of choice when it comes to mounting systems due to its relative low cost, robustness, infinite recyclability potential, and its long-term durability when combined with the latest generation of protective coatings against corrosion. Given these benefits, and combined with new production technologies, the use of steel will continue to grow in popularity when it comes to the engineering and manufacturing of mounting structures with a minimised environmental footprint.

Backing up these assertions, pv magazine Webinar partner, ArcelorMittal, a leading supplier of steel and a major actor in the solar industry, will join us to talk about its foray into the world of low CO2 steel and present solutions to improve mounting structure design, durability, and environmental impact.

One of the company’s focuses is to promote the adoption of higher strength steel products which have the potential to reduce the weight of components by up to 30% via structural design optimization, to reduce costs and, simultaneously, lower CO2 emissions.

It is also continuing to strengthen the corrosion resistance of its Magnelis® coated steel to increase the lifetime of solar investments. Complementing this, is the product’s design and manufacturing process, which uses less natural resources and generates less run-off in soil and water, among other benefits.

Overall, ArcelorMittal’s goal is to create a circular steel economy. To achieve this, it has launched its XCarb® program, and has already earmarked US$10 billion to reduce its European CO2 emissions intensity by 35% by 2030 and be carbon-neutral by 2050. The program encompasses circular carbon and carbon storage projects, and clean power generation. It further aims to use hydrogen instead of natural gas in the direct reduction of iron ore (DRI).

Join ArcelorMittal Europe’s Jérôme Guth, Solar Segment Leader, Corinne Dieu, Product leader for Metallic Coated Steels, and Hugo Campos, Sustainable Development Manager, to discover steel solutions that not only offer environmental benefits and improved durability but that can also make a significant step in achieving the sustainability goals required for your business and our planet.

pv magazine Webinar content

More info on Magnelis®: industry.arcelormittal.com/magnelis

Copyrigth banner: CWF