A new S-in motion® study from ArcelorMittal has identified potential weight savings of up to 25 percent on the body-in-white of European D-segment vehicles compared to recent models. The new study in the S-in motion® suite uses the latest advanced high strength steels (AHSS) from ArcelorMittal including Usibor® 2000 and Ductibor® 1000. Emerging grades from the Fortiform® range have also been considered.

The D-segment S-in motion® study expands on a 2015 project which looked at the lightweighting potential of steel in mid-size sedans for the North American market. In the D-segment study, which uses European standards for structural performance, multiple options have been identified for each component of the vehicle structure including the body-in-white, closures, and hang-on parts. Both hot and cold stamping options are identified in many cases. All solutions are available to carmakers anywhere in the world thanks to ArcelorMittal’s global footprint and proximity to major carmakers.

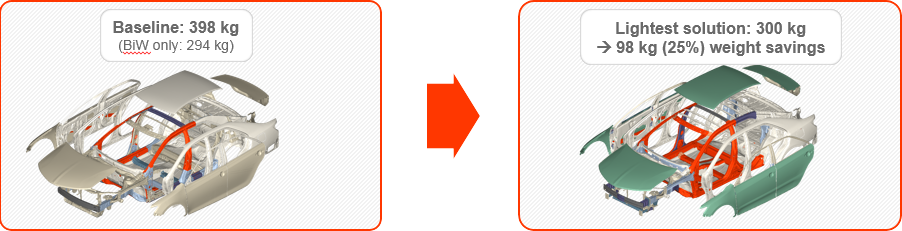

The lightest S-in motion® solution reduced weight by 98 kilograms (25 percent) at a cost of less than €2 per kilogram saved |

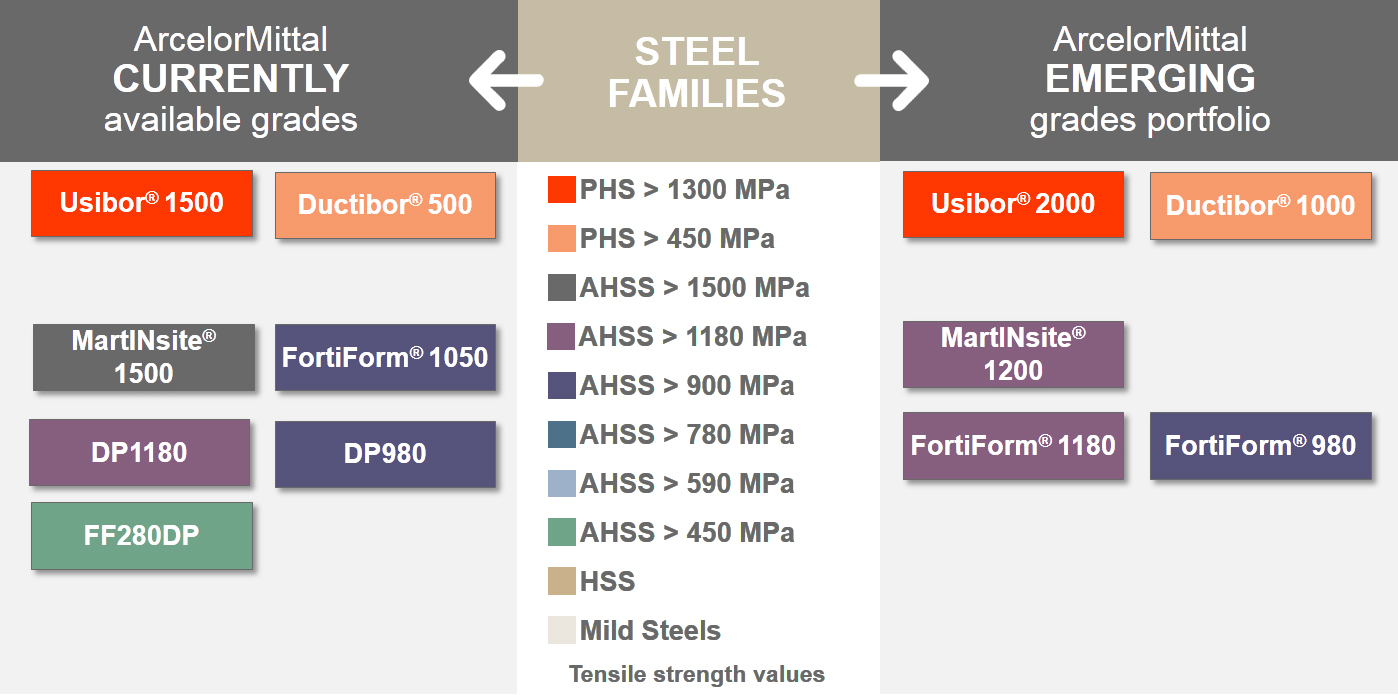

The steels tested in this S-in motion® study are cutting-edge – some of the new Fortiform® grades which are utilised in this project are still to go into full production, while Usibor® 2000 and Ductibor® 1000 have just been released. ArcelorMittal’s new grades in the Fortiform® family have proven perfect to meet the lightweighting challenge of S-in motion®. But in addition to its lightweighting potential, Fortiform® also offers high strength and excellent response to cold forming operations.

ArcelorMittal completed its offer of steel grades for hot-stamping with the release of Usibor® 2000 and Ductibor® 1000. While Usibor® 2000 provides unprecedented level of strength, Ductibor® 1000 combines high strength with excellent crash ductility. That makes it perfect for energy absorption applications. These two new steel grades can also be combined together, or with other steel grades from the Usibor® and Ductibor® families in laser welded blanks (LWBs). Usibor® will protect the safety cell from intrusions, while Ductibor® is positioned to ensure the part deforms in a controlled way in the event of an impact. Utilising these advanced steels in LWBs creates the lightest possible part but still ensures the car meets all relevant crash test requirements.

ArcelorMittal’s S-in motion® of the D-segment vehicle used new and emerging automotive grades |

As well as new automotive steel grades, ArcelorMittal is expanding its portfolio of automotive coatings. One of the latest is Jetgal® which was developed to protect very high strength cold rolled products such as Fortiform® and MartINsite®. These grades, coated with Jetgal®, are particularly useful for structural applications in the car underbody where higher strength is required. The galvanic corrosion protection provided by Jetgal® can be an asset for some OEMs in these applications.

Jetgal® is applied to the steel in a vacuum using ArcelorMittal’s patented Jet Vapor Deposition (JVD) technology. As the coating is applied in a vacuum, it remains hydrogen free and eliminates the chance the steel will become brittle.

As part of every S-in motion®, ArcelorMittal tests all of the studied steel solutions against global stiffness load cases and EuroNCAP crash requirements using finite element analysis. Typical crash tests include frontal offset, frontal rigid barrier, side moving deformable barrier (AEMDB), side pole, rear crash, and roof crush. EuroNCAP crash tests were the reference in this project and are broadly compatible with other safety car assessment programs which exist around the world, particularly those in Japan and South America. ArcelorMittal has also developed S-in motion® solutions for other vehicle categories and other testing standards. The results of these studies can be provided on request.

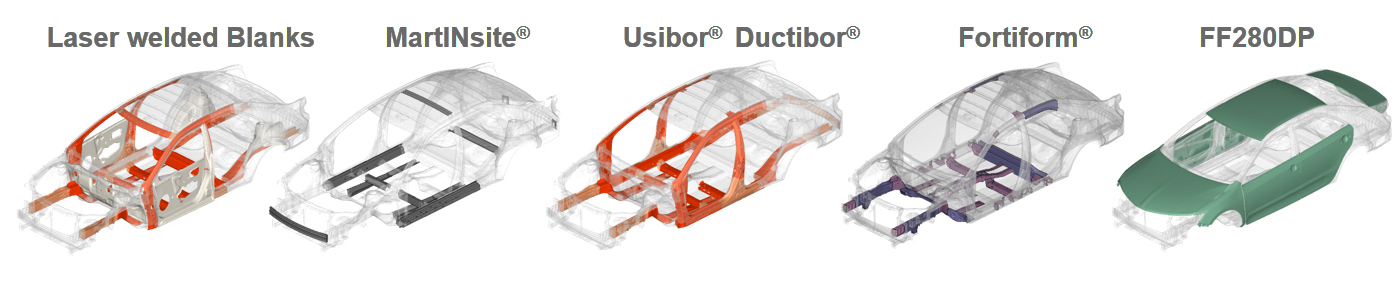

ArcelorMittal’s complete offer includes automotive steels which can lightweight all parts of the vehicle |

ArcelorMittal calculated that the weight of the body-in-white of a typical D-segment car would be reduced by 98 kilograms (216 pounds) if the lightest S-in motion® solution was used for every component. This brings the weight of the full BIW down to 300 kg, a reduction of 25-percent compared to the baseline D-segment vehicle. And the overall estimated cost is less than €2 per kilogram saved.

ArcelorMittal’s latest S-in motion® study again shows that advanced steels can be the solution to the lightweighting challenges carmakers face – and at a very cost-effective price.

Click on the picture to play the video on YouTube

Dive into the very heart of innovation with us. Our first-ever automotive 360° video gets you a never-before-seen footage of advanced steel solutions for safer and more fuel-efficient D-segment cars.

For more information please visit our Automotive website