At its recent customer day, ArcelorMittal WireSolutions unveiled a pivotal €1 million investment geared towards amplifying its control capacity in its mill of Dortmund, Germany. This move is poised to revolutionise our ability to deliver products with zero defects, precisely tailored to meet the exacting needs of the automotive industry. This strategic endeavour underscores our unwavering commitment to excellence and customer satisfaction.

The investment's impact is profound, particularly in ensuring that our hexagon and round bars adhere to the stringent quality standards demanded by the automotive sector. By leveraging cutting-edge technology and meticulously engineered processes, we are bolstering our capability to deliver flawlessly engineered components, thereby elevating industry benchmarks.

Increasing our key dimensions and capabilities

This investment highlights the magnitude of our advancements but also underscores the meticulous attention to detail ingrained in our quality assurance protocols.

Dimensions: our investment enables precise fabrication within a range of 10 to 35 mm (round) and 10 to 30 mm (hexagon), catering to a spectrum of automotive, engineering, construction and agriculture applications.

Length for testing: with bars spanning from 2,800 to 6,100 mm, we ensure a comprehensive testing coverage. Crucially, only segments less than 50 mm at the head and 30 mm at the end remain untested, ensuring rigorous scrutiny where it matters most.

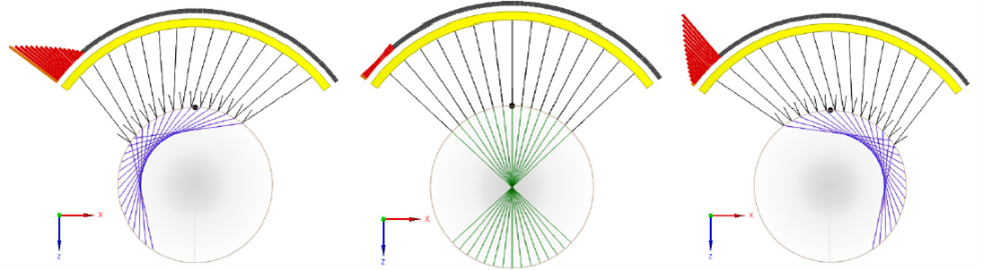

Phased array ultrasonics: employing a sophisticated array of vertical (A) and angular ultrasonic techniques, both clockwise (B) and counterclockwise (C), we enhance defect detection capabilities with unprecedented precision.

Detectable defects: Our system is adept at identifying a range of imperfections, from cracks and holes to core defects, even those perilously close to the component's edge, leaving no room for compromise in quality.

Test sensitivity: with a remarkable sensitivity of KSR 0.7 mm, our testing apparatus possesses the acuity to discern minute flaws, ensuring that no defect goes unnoticed.