ArcelorMittal has begun mass production of Magnelis® steel at its galvanising line #1 in Avilés, Spain, making the Spanish site one of the main Magnelis® production plants within the company. ArcelorMittal’s Magnelis® is a metallic coated steel that offers exceptional corrosion resistance and ensures optimal surface protection against long-term wear and tear.

Production on a large scale started in March on galvanising line #1, after several months of work to adapt the line, including a large number of tests to validate the product.

The close collaboration between the various technical teams at ArcelorMittal and the experience of the plant with this product, which started to produce Magnelis® on line #2 in 2017, have been crucial in achieving this ambitious goal.

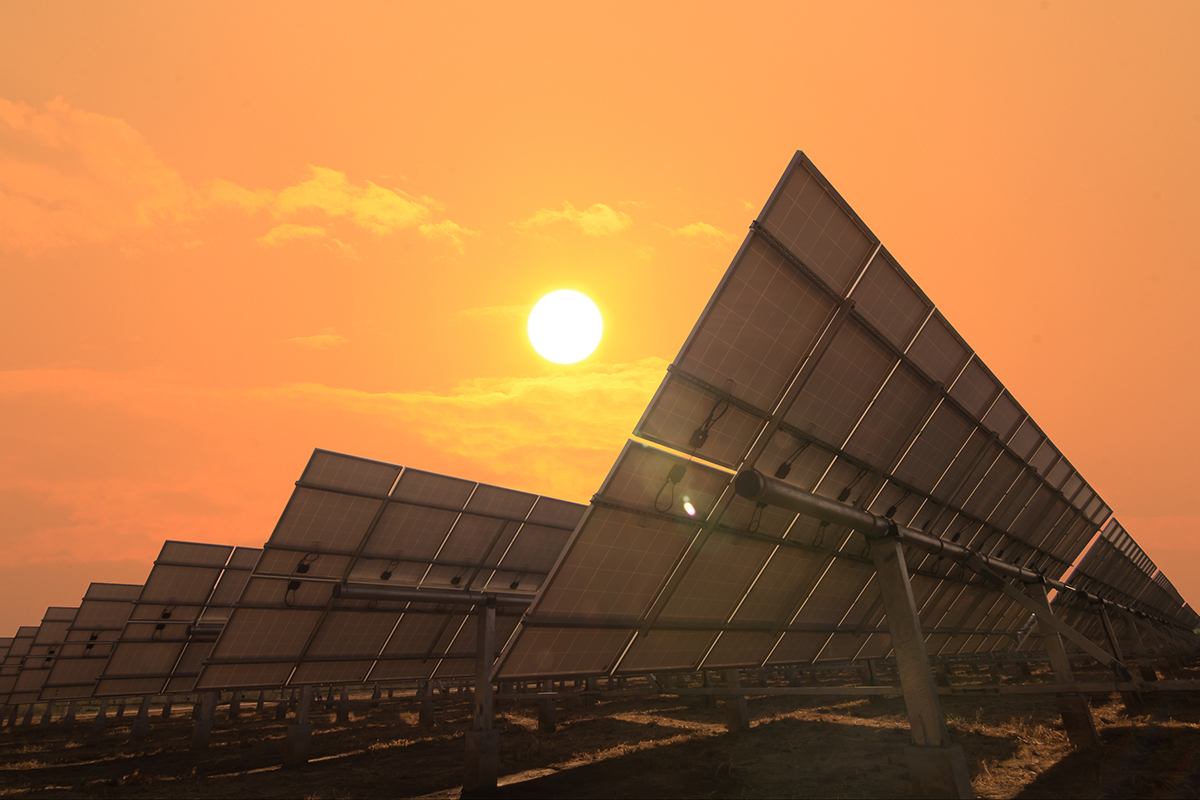

The cumulated production of more than 500,000 tonnes of Magnelis® on line #2, together with the production of heavy plate for wind towers, place ArcelorMittal Asturias as a benchmark for the production of steel used in renewable energy projects.

The production of Magnelis® on line #1 will enable ArcelorMittal to double the volume of Magnelis® produced in Asturias and will bring numerous benefits for customers in Spain. The maximum thickness of the product has been increased from 2 mm to 3.5 mm, which means that a very substantial part of the Magnelis® required by customers in the solar sector can now be supplied from Avilés. Producing Magnelis® locally will also mean shorter lead times and a significant reduction in CO2 emissions linked to transport.

This is not the only progress achieved in recent months regarding the production of Magnelis® in Avilés. It is possible to produce Magnelis® with a reduced CO2 footprint thanks to XCarb® recycled and renewably produced, which leads to a 65% reduction in CO2 emissions from the production process, compared with Magnelis® produced via the conventional steelmaking route. Moreover, thanks to the support of the Global R&D teams, it is possible to produce high strength steels coated with Magnelis®, thereby reducing the weight of structures by up to 20% and improving installation speed and quality.

In recent years, Magnelis® has established its position as the product of choice for applications in the solar sector and others such as racking systems, silos and HVAC, as it offers clear advantages over competing materials thanks to its outstanding corrosion resistance and the product guarantees issued by ArcelorMittal for every project. It provides a comprehensive solution that meets the requirements for both aerial structures and those buried in the soil. For this latter use, ArcelorMittal has developed a range of thicker coatings (ZM620 and ZM800) that can be covered by guarantees of up to 25 years for applications in different types of soils.

Credits images: ArcelorMittal - mvtstockshot/Shutterstock.com