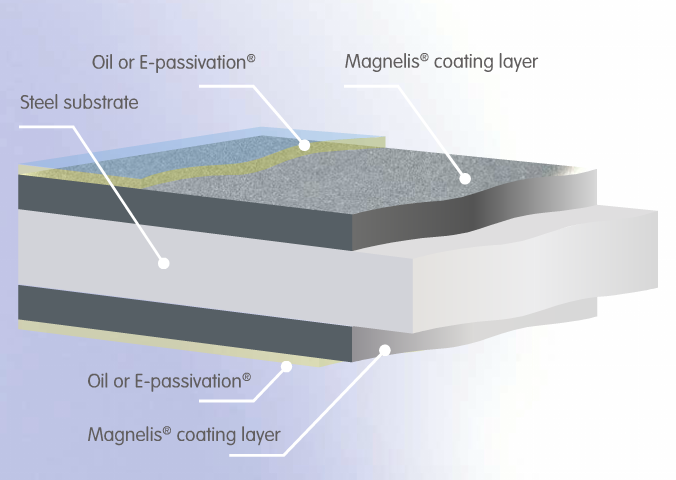

The structure of La Fossette solar farm was entirely made with Magnelis®, an ideal material for solar applications. Its remarkable corrosion resistance comes from its unique composition; developed by ArcelorMittal Europe – Flat Products, the coating includes zinc, 3.5% aluminium, and 3% magnesium. Magnelis® has a self-healing effect on cut edges and scratches which ensures excellent edge protection, even in the most hostile environments. When exposed to the environment, Magnelis® forms a very dense, zinc-based protective film. This film also forms on edges, welds, perforations, and scratches. It is almost impossible for the environment to penetrate this film.

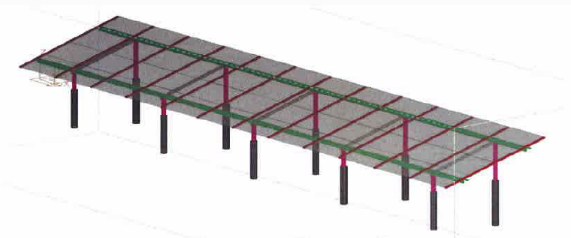

La Fossette is the first project that EDF Energies Nouvelles realises with Magnelis®. Since 2012, Profil du Futur has made continuous efforts to make Magnelis® known as a suitable product for solar applications. This prescription as well as the 25-year guarantee were key factors which convinced EDF Energies Nouvelles to work with us.

Magnelis® wasn’t the only ArcelorMittal product used for this project. ArcelorMittal Fos-sur-Mer provided slag to consolidate the paths on the solar farm. Steel-making slag is a by-product of the steel production and often used in civil engineering to consolidate embankments.

A fruitful collaboration for Fos-sur-Mer

The completion of this project is part of the EDF Group's CAP 2030 strategy, which aims to double its renewable capacity by 2030. For ArcelorMittal Méditerranée, the aim is to facilitate the production of renewable energy by making parts of its industrial lands available. The last 5 years, the company invested €60 million for sustainability and remains attentive to the residents’ remarks.

.jpg)