“The curved T-sections are probably the most visible part of ArcelorMittal’s work in this project. However, our expertise is not only there! Thanks to XCarb® recycled and renewably produced steel in Arcorox® weathering quality, the new cycle and pedestrian bridge is sustainable and designed to last, with ultra low life cycle costs. And that is what I am really proud of when I take a ride on the bridge with my cycling friends.”

Christian Thiel, Head of Technical Sales Steligence® Fabrication Centre

On top of XCarb® recycled and renewably produced steel, every single tonne of steel has been delivered in ArcelorMittal’s innovative range of Arcorox® weathering steel.

When designed with Arcorox® weathering steel together with XCarb® recycled and renewably produced, the bridge meets all cost, design and strength requirements, while achieving tomorrow’s most stringent embodied carbon and safety targets.

A bridge with Arcorox® sections is designed to last: no need for a protective coating now or in the future: maintenance is low, safety and usage remain high.

More information about the cycle and pedestrian bridge project

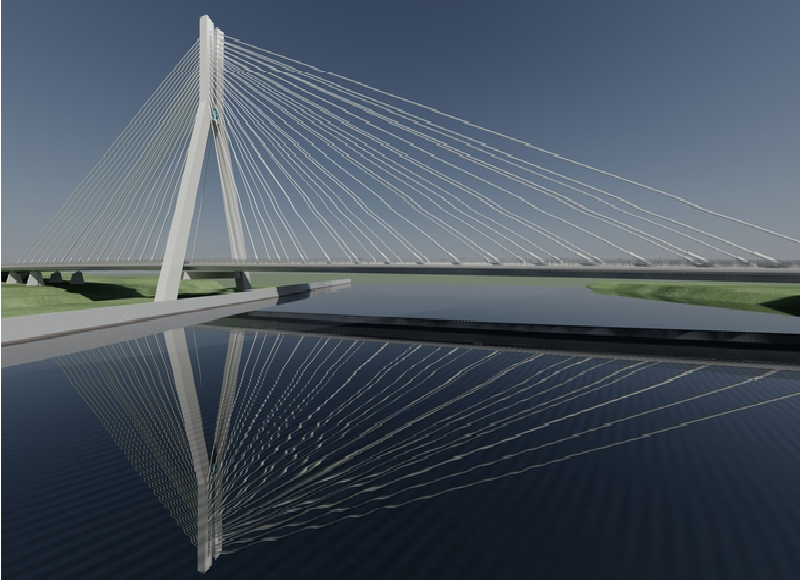

The bicycle and pedestrian bridge, linking Esch-sur-Alzette to Esch-Belval, is the longest one of its kind in Europe. The main segment between Esch/Alzette and Belval was completed at the end of 2022.

Ready for a virtual tour? Watch the video!

Read the full article about the project: The curves of Europe’s longest cycle bridge are made from XCarb® recycled and renewably produced steel

Want to know more about XCarb™?

The XCarb™ initiative, launched by ArcelorMittal in March 2021, brings together all of ArcelorMittal’s reduced-, low-, and zero-carbon products and steelmaking activities.

Scrap and renewable energy: the levers of low CO2 steel

To produce XCarb® recycled and renewably produced steel, ArcelorMittal uses up to 100% scrap and renewable electricity coming from renewable sources such as solar and wind power.

ArcelorMittal estimates that XCarb® recycled and renewably produced steel has a carbon footprint as low as 0.3 tonnes of CO2 per tonne of steel product when the metallics are 100% scrap, which is certified by a published Environmental Product Declaration (EPD).