ArcelorMittal, LanzaTech and Primetals Technologies announce partnership to construct breakthrough €87m biofuel production facility

13 July 2015 - ArcelorMittal, the world’s leading steel and mining company, LanzaTech, the carbon recycling company, and Primetals Technologies, a leading technology and service provider to the iron and steel industry today announce they have entered into a letter of intent to construct Europe’s first-ever commercial scale production facility to create bioethanol from waste gases produced during the steelmaking process. The resulting bioethanol can cut greenhouse gas emissions by over 80 per cent compared with conventional fossil fuels. It will predominantly be used in gasoline blending, but it can also be further processed into other products such as drop in jet fuel.

Click to enlarge

|

The 47,000 ton ethanol/annum project, sufficient to fuel half a million cars with ethanol blended gasoline, will demonstrate the added value of recycling waste streams, not only by reducing emissions at source, hence reducing ArcelorMittal’s direct carbon footprint, but by keeping fossil fuels in the ground through the production of commodity chemicals and fuels that would otherwise be made from oil.

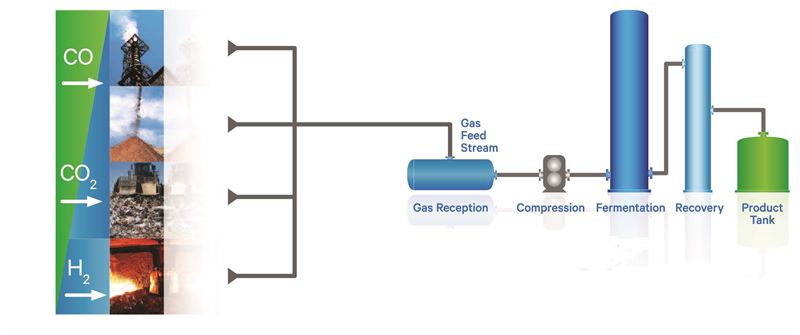

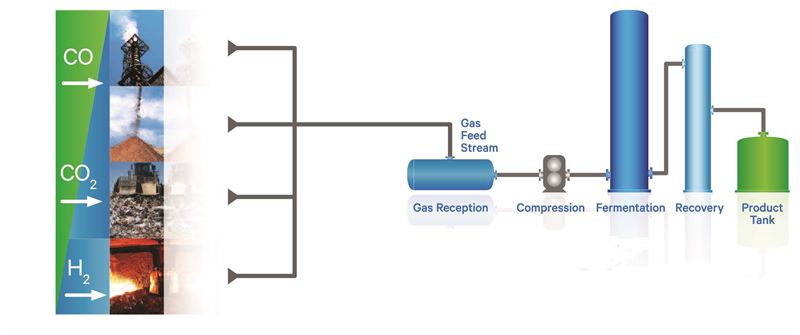

Approximately 50 per cent of the carbon used in the chemistry of steelmaking leaves the process as carbon monoxide. Today, this waste gas stream is either flared or used to heat and power the steel mill. In either case, the carbon monoxide is combusted and the resulting CO2 is emitted. LanzaTech’s technology, however, recycles the waste gases and ferments them with a proprietary microbe to produce bioethanol. Every ton of bioethanol produced, displaces 5.2 barrels of gasoline as well as reducing ArcelorMittal’s CO2 emissions by 2.3 tons.

LanzaTech’s carbon recycling technology was recently awarded the United States’ highest green chemistry honor, the Environmental Protection Agency (EPA) Presidential Green Chemistry Award. LanzaTech is collaborating with companies across multiple sectors including US aircraft manufacturer Boeing and Japanese industrial conglomerate Mitsui.

Construction of the €87 million flagship pilot project, which will be located at ArcelorMittal’s steel plant in Ghent, Belgium, is anticipated to commence later this year, with bioethanol production expected to start mid-2017. Construction will be in two phases, with phase one providing an initial capacity of 16,000 tons of ethanol per annum by mid-2017 and phase two, which will be completed in 2018, bringing the total capacity to 47,000 tons of ethanol per annum.

ArcelorMittal, which has been working on this project since 2011, has signed a long-term partnership agreement with LanzaTech. Hence, once construction of the Ghent flagship plant is complete and the commercial viability of the project is proven, the intention is to construct further plants across ArcelorMittal’s operations. If scaled up to its full potential in Europe, the technology could enable the production of around 500,000 tons of bioethanol a year.

“This partnership is an example of how we are looking at all potential opportunities to reduce CO2 emissions and support a transition to a lower carbon economy,” said Carl De Maré Vice President, Innovation, ArcelorMittal. “Steel is produced through a chemical process that results in high levels of waste gases being emitted; this new technology will enable us to convert some of these waste gases into fuels that deliver significant environmental benefits when compared to conventional fossil fuels. It is a further example of why our carbon footprint should be viewed on a life cycle analysis basis, given steel is 100% recyclable and the material impact we make on reducing the carbon footprint of our customers through product innovation.”

“ArcelorMittal and Primetals Technologies have consistently stayed on the cutting edge of innovation in the steel industry and have demonstrated their commitment to reducing their carbon emissions,” said Jennifer Holmgren, CEO of LanzaTech. “We are tremendously excited to announce this partnership and our first production facility in Europe at a time when it is abundantly clear that we need all solutions and the commitment of large corporations, cities and countries around the world, to help us stay within our 2 degree carbon budget and keep fossil reserves in the ground.”

As the production of bioethanol is a new activity, ArcelorMittal intends to set up a dedicated company for the roll out of this technology with strategic financial partners. Financing will be sought from a number of different sources. A total of €10.2 million has been secured under the EU’s 2020 Horizon programme for research and development and talks are currently taking place with potential equity and debt partners.

Primetals Technologies will be responsible for part of the engineering, automation, key equipment and commissioning.

“We are excited to be a partner in this leap-frog project with LanzaTech and ArcelorMittal. Once in operation, it will become a game changer within the industry and a benchmark for low-carbon footprint steelmaking”, said Karl Purkarthofer, Senior Vice President of Primetals Technologies.