First quarter 2015 Ebitda increased by 23.3 per cent, to €546m compared with €443m in the last quarter of 2014. Ebitda in Q1 2015 was also 40 per cent higher than in the corresponding quarter of 2014, reflecting improved demand dynamics and the ongoing realisation of the benefits of cost optimisation efforts.

Steel shipments in the first quarter increased by 10.9 per cent to 10.7 million tonnes, compared with Q4 2014, as both flat and long product shipment volumes benefitted from seasonal impacts and improved underlying demand.

Sales in the ArcelorMittal Europe segment increased by 5.9 per cent to €7.6bn this quarter compared to Q4 2014. This was primarily due to higher steel shipments partly offset by lower average steel selling prices.

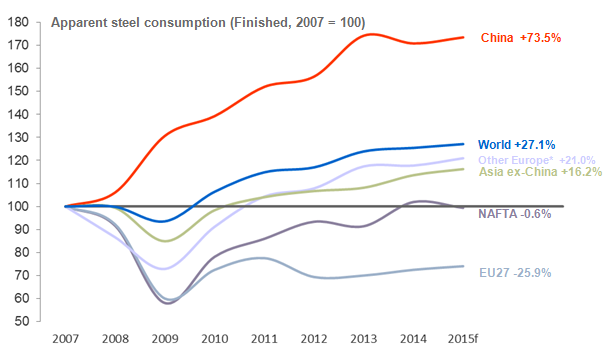

Commenting, Aditya Mittal, CEO ArcelorMittal Europe, said: “Ebitda improved again this quarter proving further evidence that the actions taken to improve the competitive position of our European operations were the right ones, and are delivering results. It’s important to note that we have achieved this in a European market where demand remains significantly below pre-crisis levels. Looking ahead, we expect to see continued pick-up in European manufacturing activity to support our apparent steel consumption growth forecast for Europe of around 2 per cent this year, and are very well placed to capture our share of improving demand.”

Confidence has picked up in the European market and is expected to slowly gain momentum. Factors such as quantitative easing, the weak Euro, low oil prices and reduced fiscal headwinds are expected to drive a recovery in growth for the Eurozone in 2015 and 2016. In addition, manufacturing output for the EU28 has reached its highest level since 2008.